Lessinia Stone

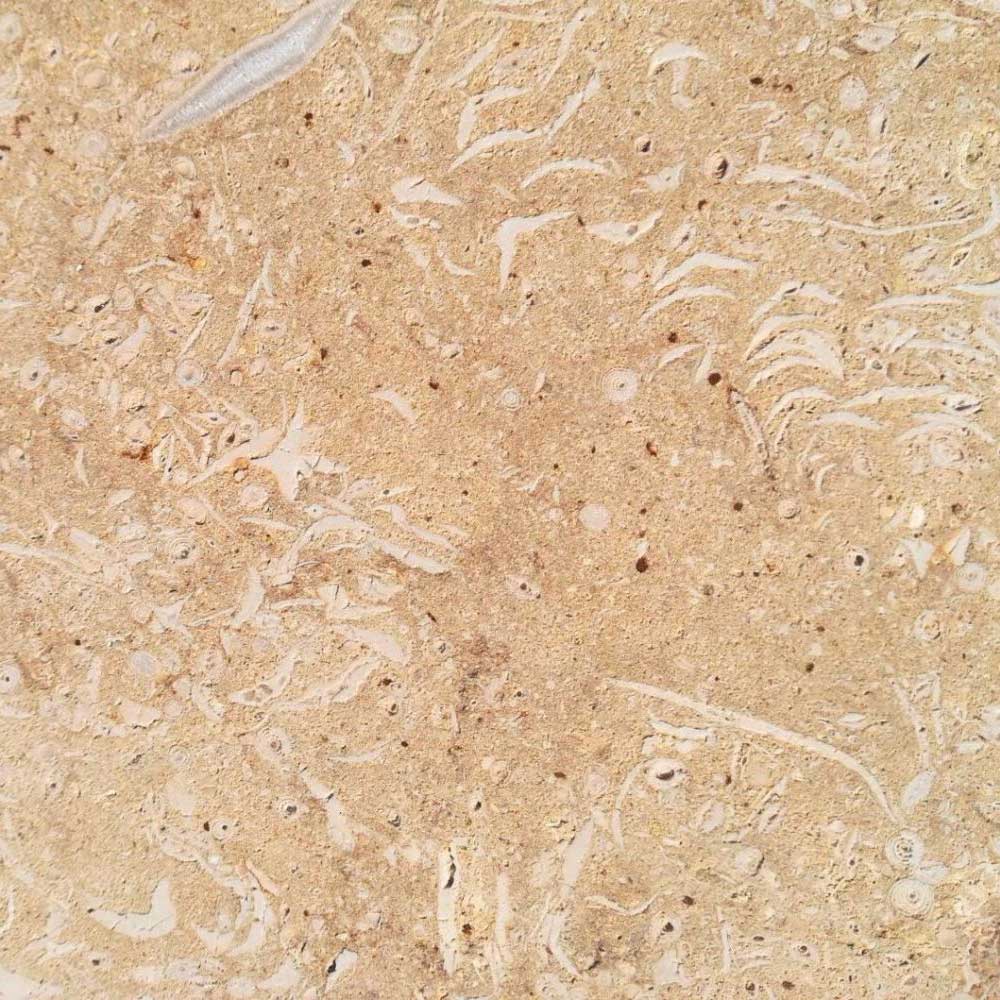

In the high valley of Negrar, in Valpolicella, near the ancient demic centers of Prun, Fane but also in Sant'Ambrogio and its surroundings, the Prun stone has been quarried in the tunnel for centuries, today more commercially known as stone of the "Lessinia".

The landscape is marked by the monumental entrances of ancient slabs quarries of particular rocky levels of the Scaglia Rossa Veneta. Its peculiar characteristic is that of constantly presenting, in a section with a thickness of about 8 meters, 73 very regular layers of white-pinkish, modular marly limestones, already naturally separated from each other by a thin veil of clay that facilitates their detachment. This dense and regular stratification has thicknesses ranging from 3 to 20 centimeters and rare and isolated levels of 30-35 centimeters. The color of the rock is variable, with shades ranging from white, to gray and golden. In Valpolicella it has been quarried for centuries, even if at present the studies on the subject do not provide any insight into whether the spectacular Prun quarries could be of Roman, medieval or modern origin. Certainly small preare (stone quarries) existed in the area, as in all of Lessinia and in the Veronese hills, since prehistoric times. In fact, remains of prehistoric houses entirely in stone have been found, from the roofs, to the side walls, to the pavements.

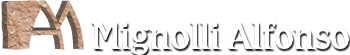

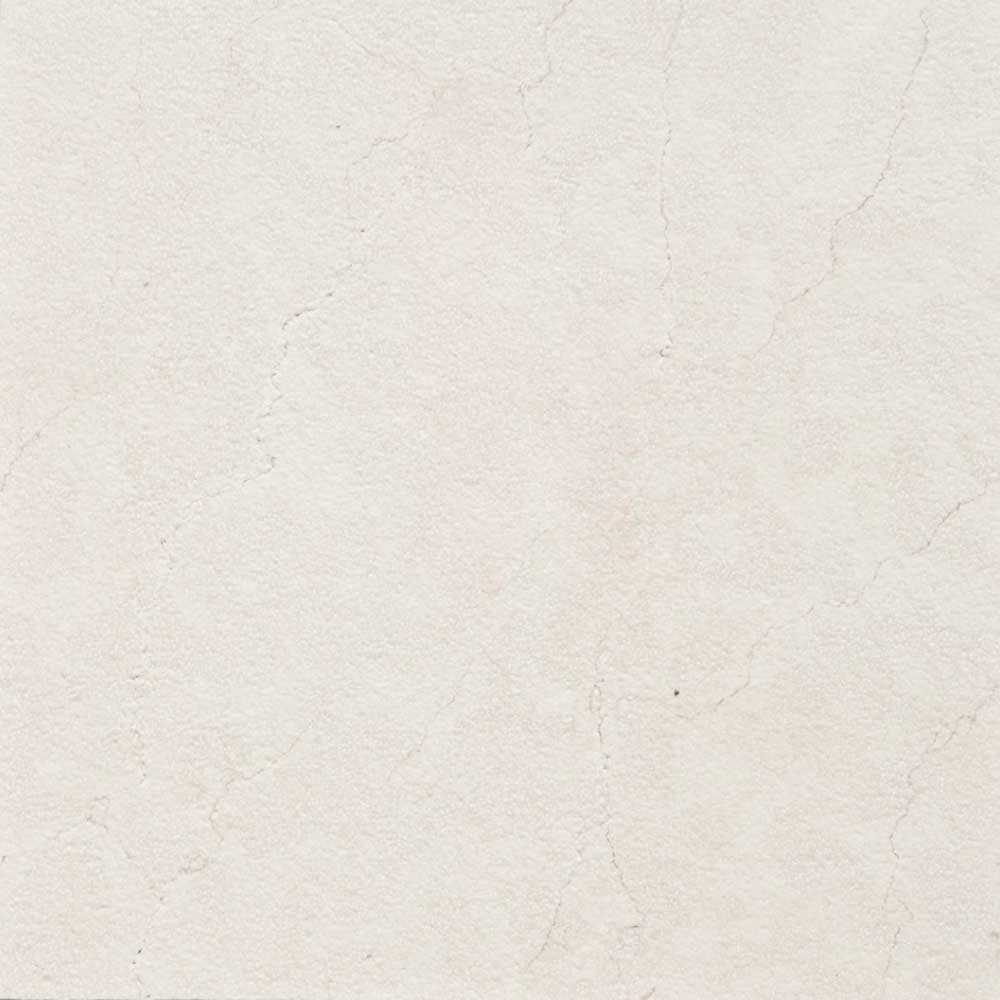

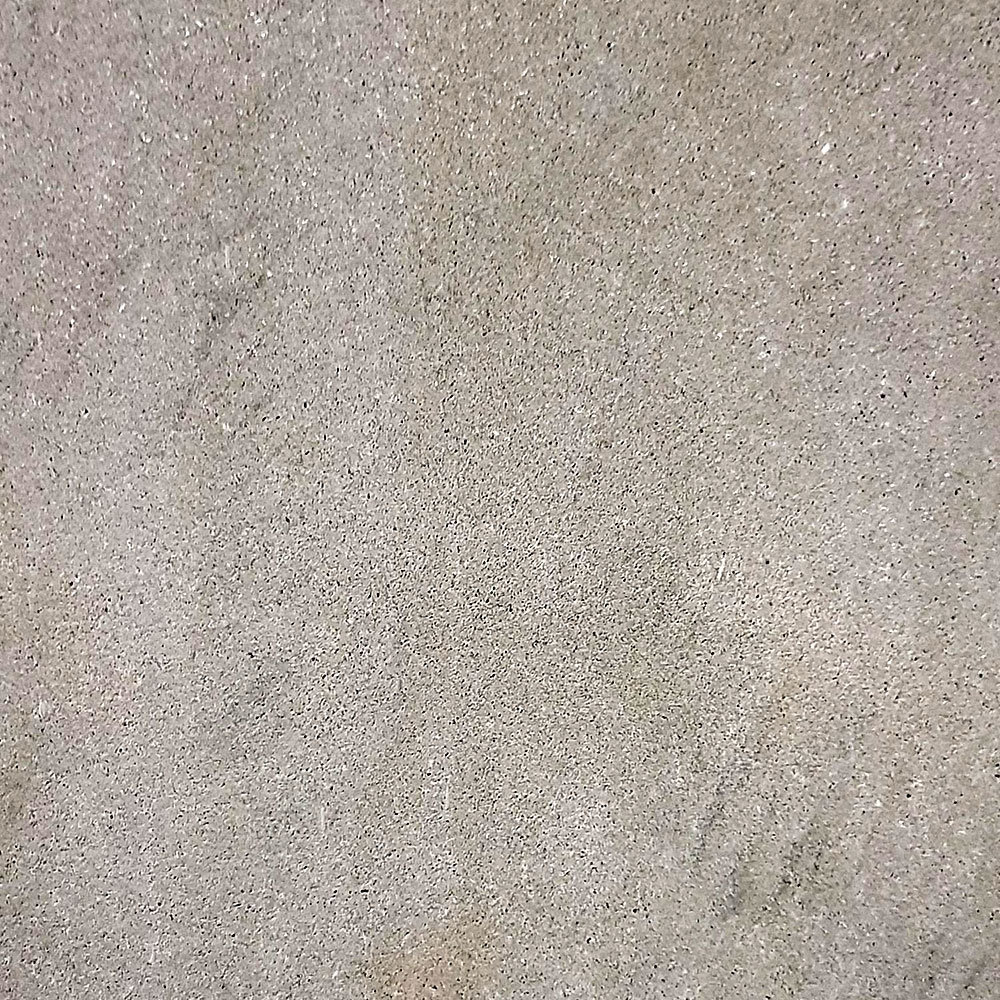

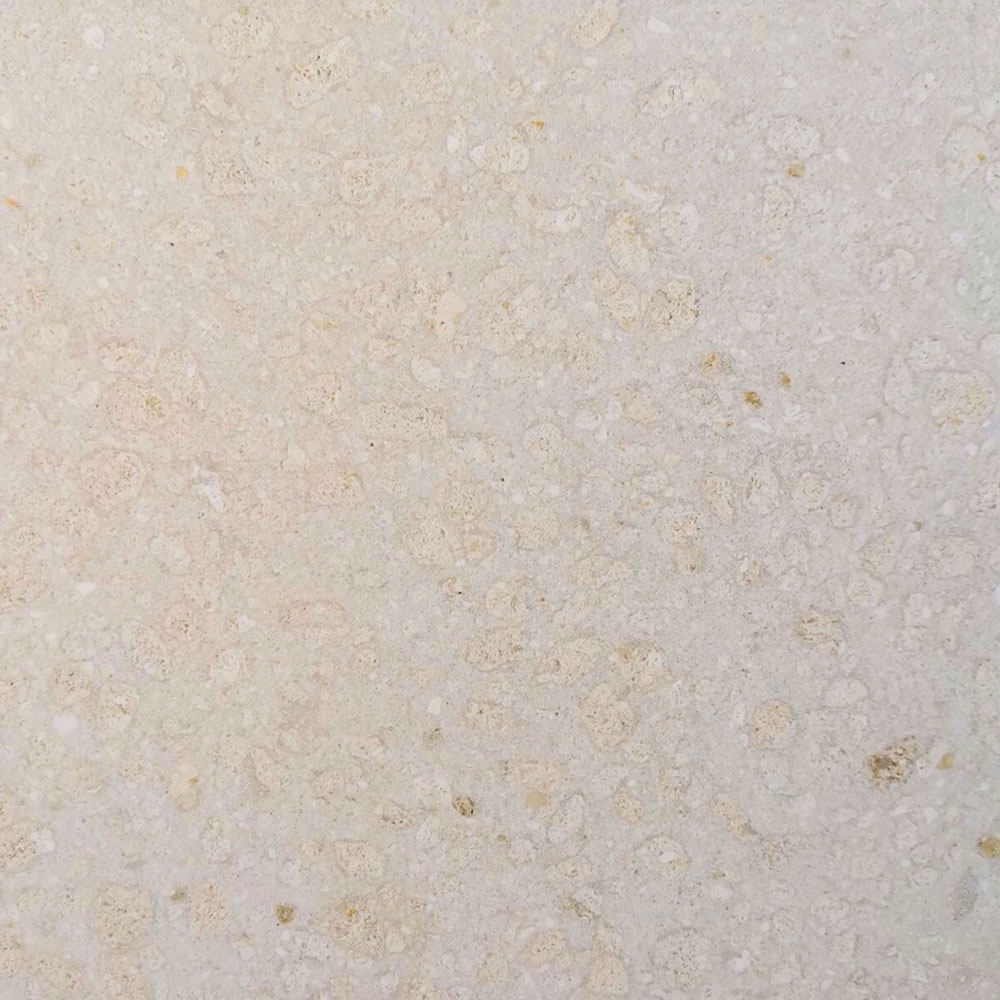

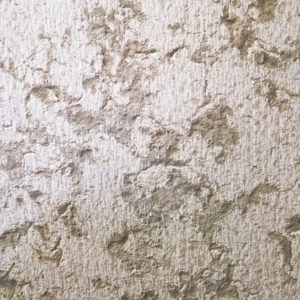

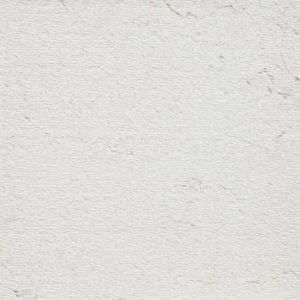

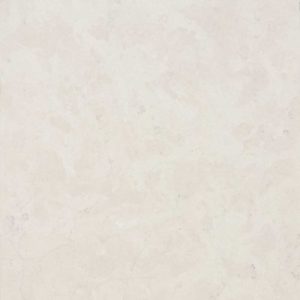

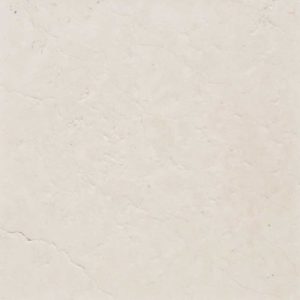

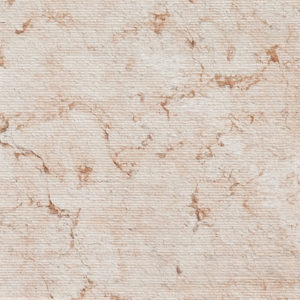

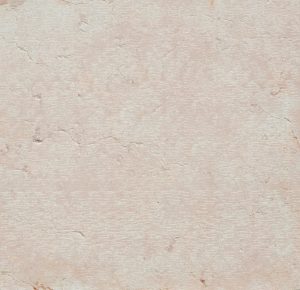

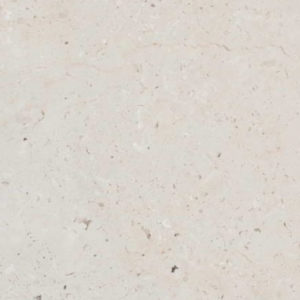

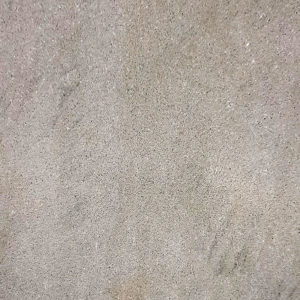

White Lessinia Stone

The Lessinia/Prun stone is unique in its kind and has a very uniform greyish-white colour. Only a few layers inside the quarry have these characteristics, making this material very rare and sought after. The Bianca della Lessinia/Prun stone lends itself to multiple processes such as: external and internal floors, external and internal cladding, borders and padding of doors and windows, swimming pool edges, coverings / wall copings for low walls, internal and external stairs, internal design elements such as tables, seats, benches, kitchen tops, buckets, sinks, bathroom furniture, fireplace cladding, planters, fountains, objects and much more.

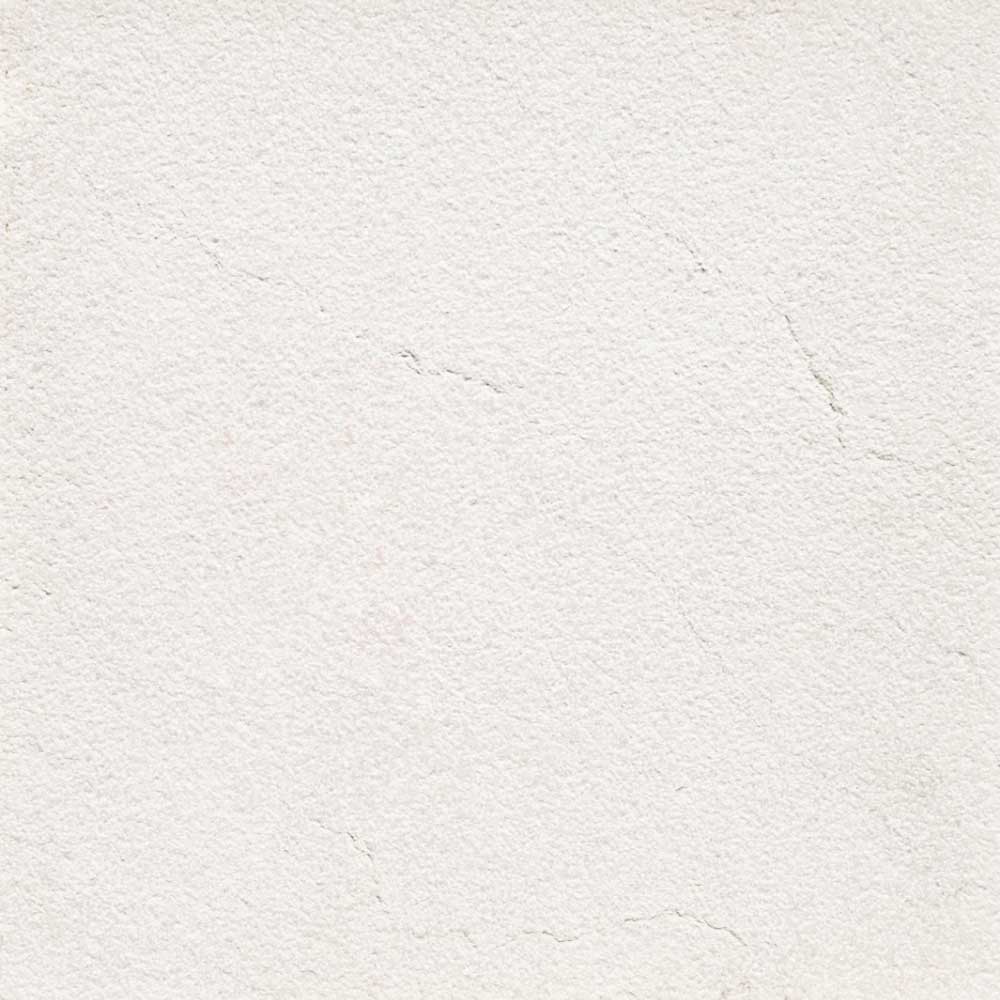

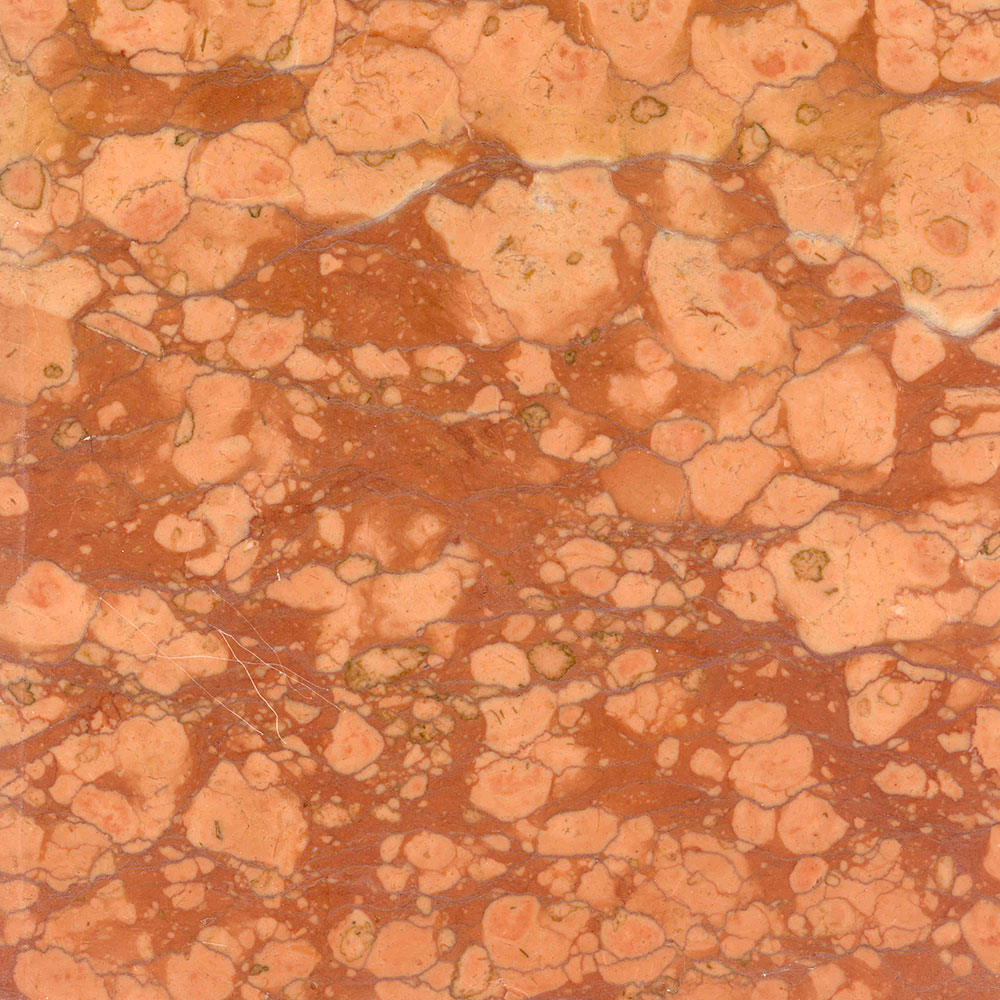

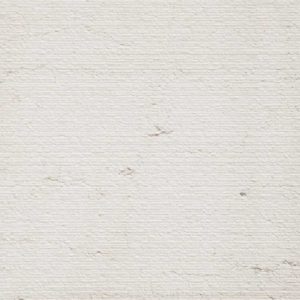

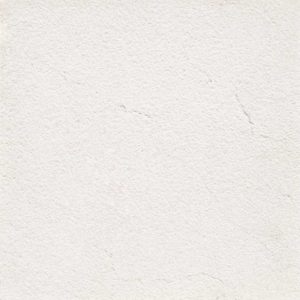

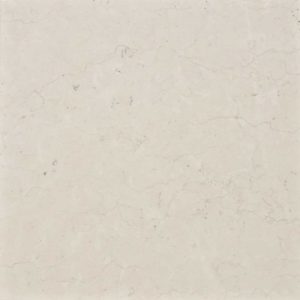

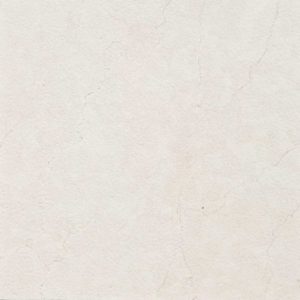

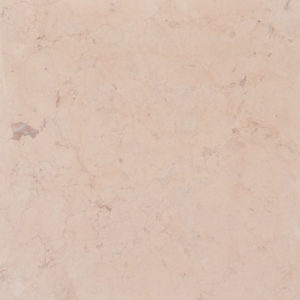

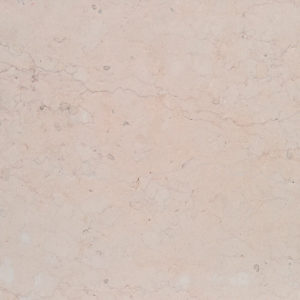

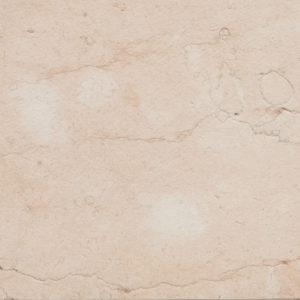

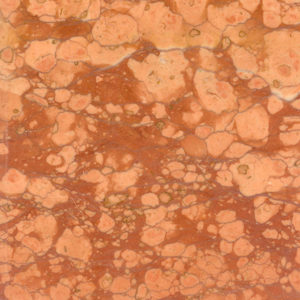

Pink Lessinia Stone

Rosa Lessinia/Prun is the typical and characteristic material of the city of Verona and its province. Historically used for the construction of walkways, coverings, roofs, bridges and historical monuments; this material helps to give value and elegance to the environments in which it is used. Whether it is used indoors or outdoors, whether it is inserted in rustic or modern environments, Rosa della Lessinia/Prun stone is a ductile and durable material over time. The Rosa della Lessinia/Prun stone lends itself to multiple processes such as: external and internal floors, external and internal cladding, borders and padding of doors and windows, pool edges, coverings / wall copings for low walls, internal and external stairs, internal design elements such as tables, seats, benches, kitchen tops, buckets, sinks, bathroom furniture, fireplace cladding, planters, fountains, objects and much more.

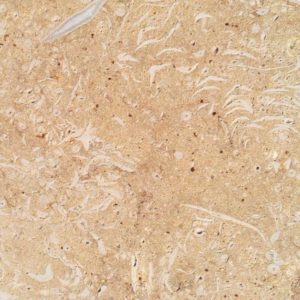

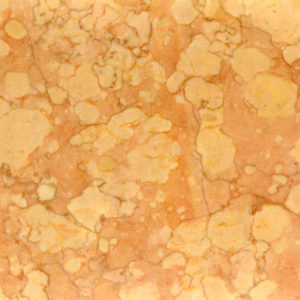

Other Stones

In addition to the "Lessinia" stone, Mignolli Alfonso snc uses a wide variety of natural marbles such as: Trani, Biancone di Vicenza/Bianco Perlino, Botticino, Giallo Atlantide, Travertino, Tufo di Vicenza, Rosso Verona.

Processing

The stone of "Lessinia" due to its great resistance and ductility is suitable for any type of processing such as quarry splitting, scratching on the hollow split, machine scratching on the sawn wood, hand scratching on the sawn wood, bush hammering and brushing, sandblasting, sandblasting and antiquing. , sanding, polishing, brushing etc ..

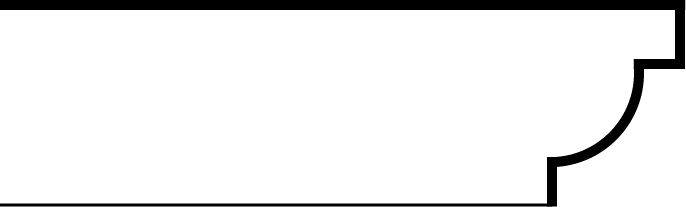

COSTA RETTA

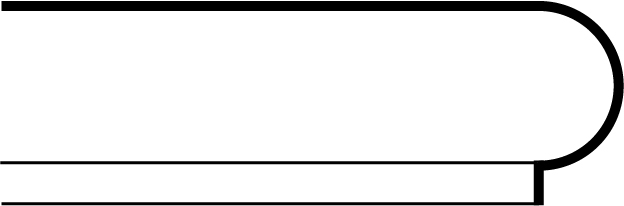

COSTA A TORO CON LISTELLO

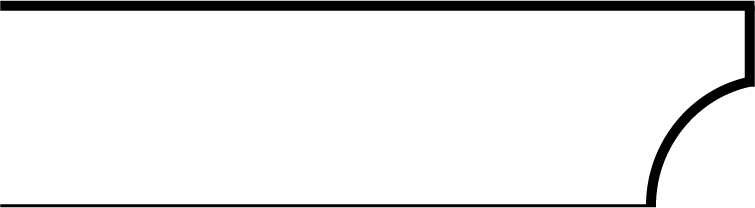

COSTA A MEZZO TORO CON LISTELLI

COSTA A GUSCIA

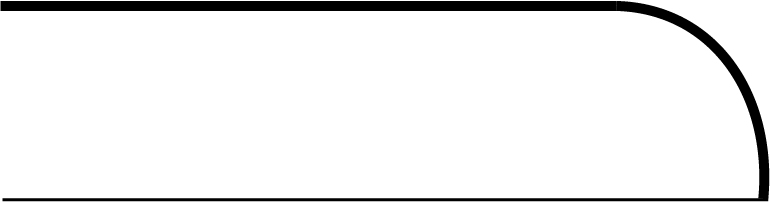

COSTA A MEZZO TORO

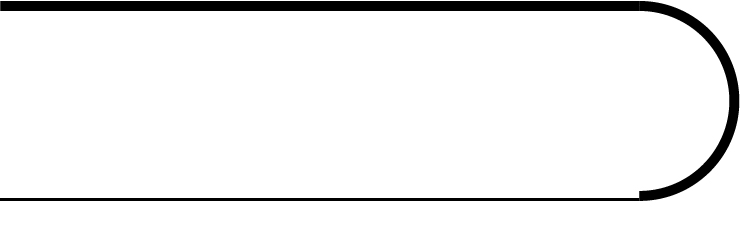

COSTA A TORO

Lessinia Stone Technical Sheet

| PINK | WHITE | |

| Main Use | Indoor/Outdoor | Indoor/Outdoor |

| Weight per volume unit | 2660/2690 kg/m3 | 2660/2690 kg/m3 |

| Average flexural strength of the results of the 10 Rtf assays Standard deviation S |

11.2 Mpa 0.6 Mpa |

16.6 Mpa |

| Determination of resistance to freezing / thawing in compliance with the EN 12371: 2001 Average flexural strength after 48 freeze / thaw cycles Rtf Standard deviation S. Decreased flexural strength after 48 freeze / thaw cycles compared to simple flexural strength |

9.8 Mpa |

16.9 Mpa |

| Determination of the compressive strength in compliance with the EN 1926: 1999 Average compressive strength Rm Standard deviation S. Coeficient of variation V. |

140 Mpa |

186 Mpa |

| Determination of resistance to freezing / thawing in compliance with the EN 12371: 2001 Average compressive strength after 48 freeze / thaw cycles Rm Standard deviation S Coeficient of variation V Decreased compressive strength after 48 freeze / thaw cycles compared to simple compressive strength |

136 Mpa 3% |

172 Mpa |

| Determination of resistance to abrasion according to appendix C UNI EN 1341: 2003; appendix B UNI EN 1342: 2003 Calibrated abrasion value, average of the results of the 6 assays Calibration value recorded |

19.7 mm |

19 mm |

| Water absorption at atmospheric pressure according to the EN 13755: 2001 Water absorption at atmospheric pressure, average value of the 6 samples |

1.2% | 0.42% |

| Determination of resistance to slipperiness in compliance with appendix D UNI EN 1341: 2003; appendix C UNI EN 1342: 2003

Overall average (USRV) sliding element and wet specimen: |

54 |

55 |